Providing State-of-the-Art Heat Sealing Solutions for Tissue Banking

Tissue Banks Processing

Tissue Banks Processing

Time-sensitive processing commences within specified time limits. The tissue banks are managed under suitable environmental conditions and through methods that have been validated to prevent contamination and cross-contamination for tissue banks.

Why PackworldUSA Impulse Sealing?

PackworldUSA validatable impulse heat sealers provide several advantages to tissue banks when used to create sterile barrier systems or other hermetic heat seals. Impulse technology allows for sealing the widest variety of films including Polyethylene, nylon, Tyvek and more. High temperature heat sealing is also possible. Bonding fluoropolymer films such as PTFE, PFA, FEP are common applications. Impulse sealing allows for quick machine start up instead of waiting 15 minutes for a hot bar to achieve sealing temperature. Unlike hot bars, impulse is less likely to radiate temperature into sensitive product in close proximity to the heat seal mitigating temperature related product damage.

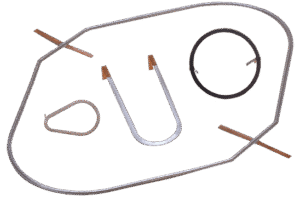

Tailor-made assures Perfect Seals... Every Time!

Custom engineering capabilities allow PackworldUSA to create GENUINE TOSS Alloy-20® contoured seal paths tailored to specialized pouch configurations, ensuring hermetic seals even for non-standard shapes.

Superior Impulse Heat Sealing Process Control

Traditional impulse heat sealing controls only apply a fixed amount of energy with no temperature feedback loop. This creates variable seal results as the machine retains heat through production and starts to overmelt seals. The next iteration is to incorporate a thermocouple sensor-based temperature feedback loop but this technology has its own challenges including slow temperature read times, misplacement or movement of the sensor, and eventual degradation.

Traditional impulse heat sealing controls only apply a fixed amount of energy with no temperature feedback loop. This creates variable seal results as the machine retains heat through production and starts to overmelt seals. The next iteration is to incorporate a thermocouple sensor-based temperature feedback loop but this technology has its own challenges including slow temperature read times, misplacement or movement of the sensor, and eventual degradation.

PIREG Impulse Heat Seal Control

TOSS technology utilizes the PIREG impulse heat seal controller to eliminate the need of thermocouple temperature management by directly monitoring the resistance of the heat seal band itself. Resistance is correlated to temperature and read 50-60 times per second. Robust electronics allow for extremely fast heating of the seal bands such as 400ms to heat to 300C (572F). Machines can also be programed to gradually ramp to specific set temperatures.

TOSS technology utilizes the PIREG impulse heat seal controller to eliminate the need of thermocouple temperature management by directly monitoring the resistance of the heat seal band itself. Resistance is correlated to temperature and read 50-60 times per second. Robust electronics allow for extremely fast heating of the seal bands such as 400ms to heat to 300C (572F). Machines can also be programed to gradually ramp to specific set temperatures.

Backed by Excellence

PackworldUSA stands behind its products with a 30-month warranty on all parts (excluding consumables). Each machine is built to exacting standards, meeting the rigorous demands of packaging professionals across industries.

PackworldUSA impulse heat sealers are more than just machines – it's a commitment to quality, precision, and innovation in packaging technology. Whether you're in life sciences, pharmaceuticals, or any industry requiring top-tier packaging solutions, the PackworldUSA is ready to elevate your packaging process to new heights.

Ready to revolutionize your packaging line?

Contact PackworldUSA at sales@packworldusa.com