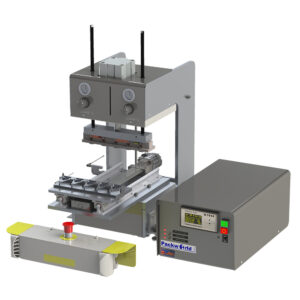

Bench Top Press Impulse Heat Sealing System

PW2200, PW2210, PW2408, PW2412, and PW2414

SAFETY AND PRECISE CONTROL. The PW2000 Series Bench top Press is the perfect solution for low volume convenience packaging or as a development laboratory tool.

Validatable, Repeatable, Consistent

This convenient table top heat sealing system works great for plastics and heat sealable composites. Composed of a rugged bench top heat seal Press and a Heat Seal Control Module, the system offers both safety and precision control of time, temperature, and pressure of the heat sealing cycle on your table top. PackworldUSA's superior performance comes from our exclusive TOSS Technology with advanced PIREG® temperature control - The Optimum Sealing System.

To ensure the versatility you need, the PW2000 Series presses can be fitted with virtually any heat seal configuration that may be required. Two pressure regulators provide for a safety close at low pressure followed by high sealing pressure when the platen is essentially closed.

Timing can be preset to within 0.1 seconds, and cooling can be controlled by either temperature or time. Actual temperature is displayed on the face-mounted digital display and is repeatable. Auxiliary ports are provided for both Data Output and Anti-tie down dual button activation.

Packworld's superior performance comes from our exclusive TOSS Technology - The Optimum Sealing System. It provides consistent and repeatable results, every time—heat seal after heat seal.

Precision Heat Seal Control

The versatile advanced PIREG® impulse heat seal controller provides digital display of menu driven time/temperature profile with various time sequence possibilities. Time and temperature are keypad programmable with the cooling cycle controlled by either time or temperature. Actual temperature is displayed in real time and repeatable. Machine can be fitted with TOSS Alloy–20®-C heatseal bands or wires depending upon the results desired.

| Models | PW2200 Control Module, PW2210 Control Module, PW2408 6 x 8” Press, PW2412 8 x 12” Press, & PW2414 14 x 14” Press |

| Applications: | Medical Devices • Pharmaceuticals • Consumer Product Goods • Cosmetics • Liquid Packaging • Samples or Specimens • Research & Development • Electronics |

| Features: | Compressed air outlet • Air pressure regulator and gauge • Low pressure closing/high pressure heat sealing • Locking Security Cover • Stainless steel case • Quick and easy change over of heatseal bands • Emergency stop button • Anti-tie down Dual Push Button Start |

| Benefits: | Calibration made simple • Precise and repeatable heat sealing control • Ease of operation • Adaptable to a wide variety of uses • Maintenance Free • Safety Assured |

| Options: | Data Capture with USB connection and PC Software • NIST traceable calibration • Adjustable • Table for exact product placement • Jaw modifications for water cooling • High Temperature Application Set-up • CE Compliance |

| Standard Features | Heat Seal Length: 16 Inches • Heat Seal Width: 4, 6 or 8 mm • Temperature Range: 0 - 500°C • Timers: 0 - 99.9 Sec • Power: 115V, 15 amp • Dimensions: 16" x 19" x 7" • Weight: 56 lbs. |

| Options | Adjustable Stainless Steel Stand • Stainless Steel product table • Water-cooled Jaws • NIST Traceable certification • CE Compliant |

| Specifications | Timer: 0 - 99.9 sec. • Temperature Range: 0 - 500°C • Jaw Force: 0 - 1000 lbs. • Size: 6 x 8, 8 x 12, 14 x 14, 24 x 44" • Air Requirements: 80 - 100 psig • Power: Various KVA @ 115V, 20 amp 220V, 20 amp |

All PackworldUSA built machines are fully validatable, ensuring that your packaging will meet even the most demanding requirements. We offer precision heat sealing equipment ranging from bench top models to floor-standing production machines, all powered by TOSS Technology with advanced PIREG® temperature control - The Optimum Sealing System - for consistent, validatable and repeatable results, every time.