Precision Medical Impulse Heat Seal Machine Products

PackworldUSA is a leading precision impulse heat seal machine manufacturer whose sole mission is to design and engineer precision controlled, validatable heat sealing equipment and products. From benchtop heat seal machine models to floor standing production heat seal equipment... all products are designed for markets where high quality, repeatable and validatable heat seals are required.

PackworldUSA products are Variable Resistance Controlled (VRC), heat sealing machines including many with vacuum/purge and seal/cut capabilities for a variety of materials and pouch shapes for the medical device, pharmaceutical, biotech and electronic industries.

PackworldUSA products are Variable Resistance Controlled (VRC), heat sealing machines including many with vacuum/purge and seal/cut capabilities for a variety of materials and pouch shapes for the medical device, pharmaceutical, biotech and electronic industries.

Along with its full line of validatable pouch sealers, PackworldUSA specializes in designing precision engineered platen press systems used for the bonding of polymeric materials and custom platens with contoured heat sealing elements designed to apply heat precisely to the heat seal area. And, all are powered by TOSS® Technology - The Optimum Sealing System for consistent, validatable and repeatable results, every time.

TOSS Technology

"The Optimum Sealing System"

All PackworldUSA Medical Heat Sealers are equipped with the advanced TOSS Technology. Unlike ordinary impulse sealers, with TOSS, Variable Resistance Control (VRC) is employed allowing the heating element to serve as its own sensing device, eliminating the inherent inconsistencies found with other heat sealer controls. Like an RTD, TOSS solely measures and controls the resistance of the entire heating element, eliminating temperature variations caused by the surrounding environment or by the possible movement of thermocouples.

Advanced Precision Clean Room Heatsealers

Fully validatable and calibratable, ISO 11607, and RoHS compliant. This clean room heat sealer, with the TOSS Touch Screen control, is designed for quality, reliable sealing of plastics and sealable composites in a Medical Packaging, Research & Development, or production environment.

TOUCH SCREEN PRECISION HEATSEAL CONTROL

TOUCH SCREEN PRECISION HEATSEAL CONTROL

Versatile Variable Resistance Control (VRC) heat sealers, with TOSS Touch Screen control, provides a graphical display of temperature/time/pressure with various time sequence possibilities and visual/audible alarms. Time, temperature and pressure are programmable with the cooling cycle controlled by either time or temperature. Process controls are displayed in real time. Validation is easier than ever through the menu driven single touch process. • AUTOCAL (automatic Zero Calibration) with multi point calibration • Recipe storage • Re-settable seal counter • Graphical temperature display • Alarm diagnostics • Password protection • Watchdog monitoring checks temperature while idle.

PASS THROUGH PRECISION HEATSEALERS

The TOSS Touch Screen control heat sealer is designed for quality, reliable sealing of plastics and sealable composites in a Medical Packaging, Research & Development, or production environment. A full width pouch, bag or web sealer constructed with a robust rubular steel frame and polished stainless steel cover and working surfaces. The PW5500 series provides an open “C” frame to allow movement side-to-side as well as pass-through.

STANDARD FEATURES

Vacuum/Purge, Vacuum Only, Seal Only • Automatic Cut-off at selected vacuum or time level. Available in 16”, 24”, 36” and 48” models • Compressed air exhaust outlet • Low pressure closing/high pressure sealing • Single or Dual band operation • °C or °F • Emergency Stop Button • Can be fitted with any one of over 300 different TOSS Alloy 20®-C heatseal bands depending on the results desired.

Medical Precision Heatsealers

These Validatable PackworldUSA Heatsealers are ISO 11607 and RoHS compliant and designed for quality, reliable sealing of plastics and sealable composites in a Medical Packaging, Research & Development or production environment. Ideal for materials testing and quantifying the optimum heat sealing parameters for seal or seal/cut applications. Convenient and easy to operate. Horizontal or Vertical sealing bars.

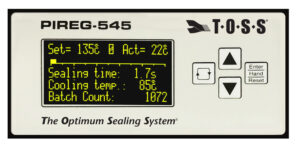

PRECISION HEATSEAL CONTROL

With TOSS Technology, Variable Resistance Control (VRC) is employed for precision temperature control. The controller provides a digital display and is keypad programmable. Our most advanced temperature heatseal controller, the PIREG®545, offers Automatic Multi-Point Calibration, Recipe Storage, Password Protection and a visual Batch Counter.

PASS THRU PRECISION HEATSEALERS

Designed to provide the ultimate in sealing simplicity while offering clean, reliable, repeatable and validatable heat sealing of plastic films and sealable composites. Recommended for clean room or production floor use, for wide pouches, bags or web sealing. Constructed with a robust tubular steel frame, polished stainless steel cover and work surfaces. The PW5100 series provides an open “C” frame to allow movement side-to-side as well as pass-through.

STANDARD FEATURES

Digital Air Pressure Gauge and Alarms • Easy calibration • All Stainless Steel Case • Low pressure closing/high pressure sealing • Single or Double band operation • Emergency Stop button

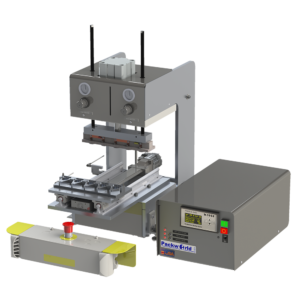

Custom Contour, Remote, and Hi-Temp Bench Top Press Systems

Convenient heat sealing systems for plastics and sealable composites can be used for low volume convenience packaging or as a development laboratory tool. Composed of a rugged Precision Bench Top Heatseal Press and a Heatseal Control Module the system offers both safety and precision control of time, temperature, and pressure of the sealing cycle.

PRECISION HEATSEAL CONTROL MODULE

With TOSS Technology, Variable Resistance Control (VRC) is employed for precision temperature control. The controller provides a digital display and is keypad programmable. Our most advanced temperature heatseal controller, the PIREG®545, offers Automatic Multi-Point Calibration, Recipe Storage, Password Protection and a visual Batch Counter.

PRECISION BENCHTOP HEATSEAL PLATEN PRESS

The press can be fitted with virtually any heatseal configuration that may be required. Two pressure regulators are provided for a safety close at low pressure followed by high sealing pressure when the platen is essentially closed. Temperature and cycle time are controlled by the Heatseal Control Module.

BENEFITS

Precise and repeatable control • Ease of operation • Adaptable to a wide variety of uses: Cutting/sealing of contoured shapes, fitment and port sealing, custom platens

PW4212 CUSTOM REMOTE OR THE PW7016 SERIES BENCH TOP

These cost effective, foot pedal switch operated, tabletop sealers are perfect for the production sealing of Tyvek, poly, foil pouches and high temperature materials. The unobstructed stainless steel top allows for ease in cleaning and the jaws are readily accessible for routine servicing.

STANDARD FEATURES

Stainless Steel Case • Double Band Operation • Recipe Storage • Seal Cycle And Machine Count • Password Protection • Multi-Point Calibration • Internal Air Compressor • Adjustable Sealing Pressure

All PackworldUSA built machines are fully validatable, ensuring that your packaging will meet even the most demanding requirements. We offer precision heat sealing equipment ranging from bench top models to floor-standing production machines, all powered by TOSS Technology with advanced PIREG® temperature control - The Optimum Sealing System - for consistent, validatable and repeatable results, every time.